NJMKT carbon fiber sheet is an uni-directional carbon fiber reinforced material made by imported carbon fiber filament. It has two kinds of thickness of 0.111mm (200g) and 0.167mm (300g), and many kinds of width: 100mm, 150mm, 200mm, 300mm, 500mm and other special width requirements, widely used for tensile and seismic reinforcement of structural components. And it can be regarded as carbon fiber composite material when used with MKT-carbon fiber impregnation adhesive, which is suitable for reinforcement of concrete and wood structure, and has reached the requirements of "Reinforced Concrete Structure Design Code GB50367-2006", This product can effectively improve bearing capacity of components, seismic performance and durability.

Advantages:

1. Imported carbon fiber filament, excellent smoothness, easily to be cut according to your desired shape regularly

2. High tensile strength of 4-8 times of ordinary steel

3. Anti-acid and alkali, corrosion resistance, suitable for any harsh environment

4. Excellent performance of winding and wrapping for various types of reinforcement, such as curved surface, strange-shape components, etc.

5. Light weight, low density, 23% of steel material, no increase of self-weight or section size to components

Light weight, easy for construction, low density, 23% of steel material, no increase of self-weight or section size to components

This flexible sheet can easily be cut according to your desired shape and have close adhesion with reinforced concrete surface, suitable for extensive shape structures

Small thickness, easy to overlap, excellent performance of winding and wrapping for various types of reinforcement, such as curved surface, strange-shape components, etc.

High tensile strength and flexibility, it can achieve the same effect of reinforced steel plate

Anti-acid and alkali, corrosion resistance, suitable for any harsh environment

The matching epoxy resin adhesive (suggested our factory manufactured carbon fiber impregnating adhesive) has good permeability, easy installation and short construction period

Non-toxic, non-irritating odor, environmentally safe, operation can be done in living situation

High tensile strength of 4-8 times of ordinary steel

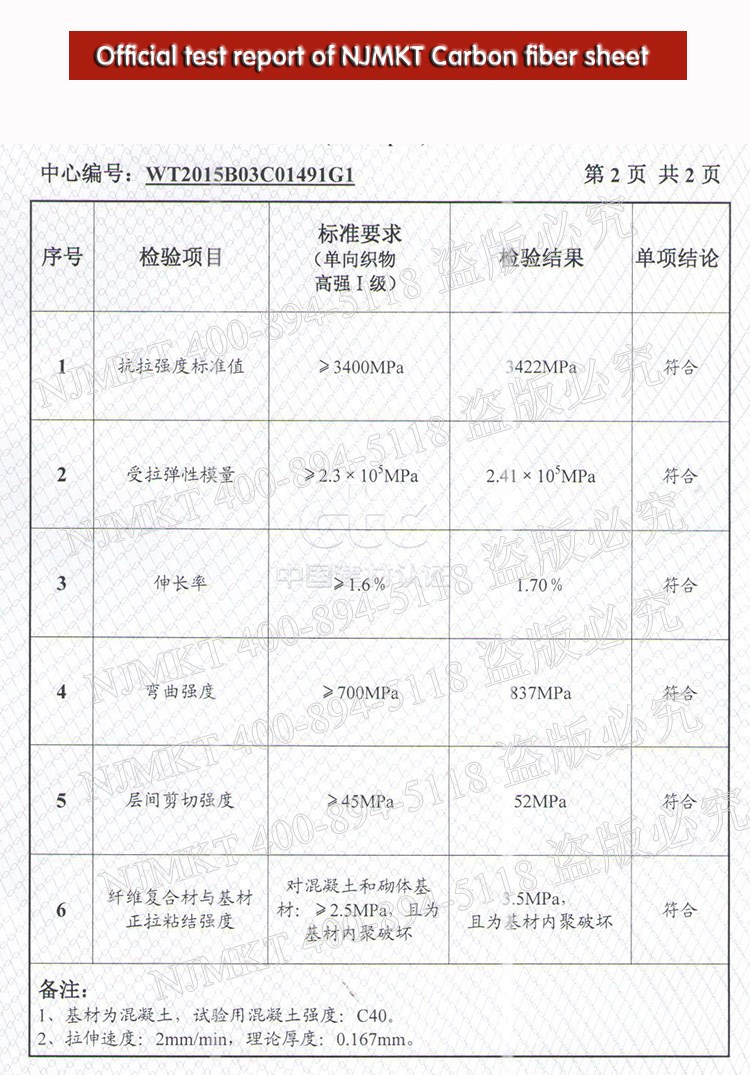

NJMKT promise to meet the technical requirements of the following GB50367-2013 "Design code for concrete structure reinforcement" and GB50728-2011 "Technical code for safety identification of reinforcement materials for engineering structures".

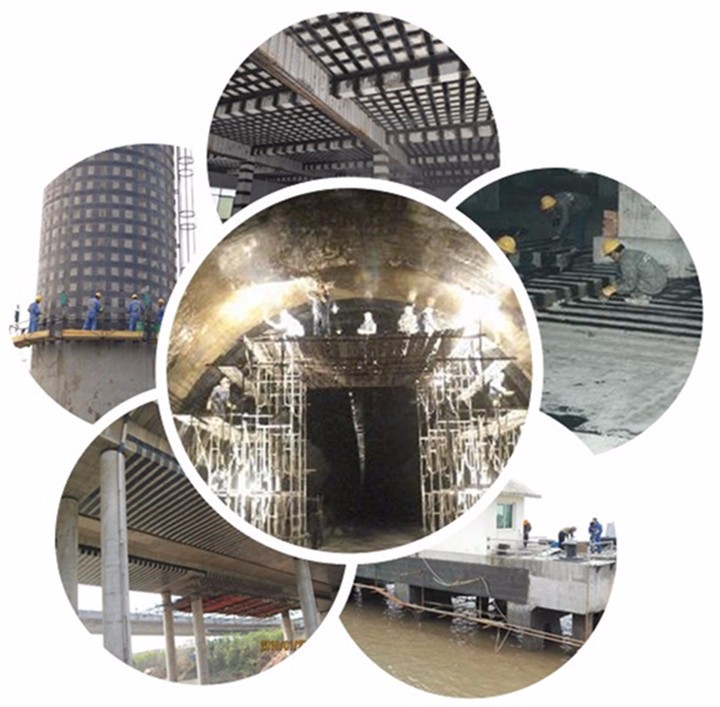

It is your outstanding option to deal with the following engineering problems:

1. Increasing building service load

2. Changing usage function of engineering projects

3. Material aging

4. Concrete strength grade is lower than the design value

5. Structural cracks treatment

6. Repair and protection for in-service components in harsh environment

7. Satellites, aircraft, sports, industrial products and many other reinforcement fields

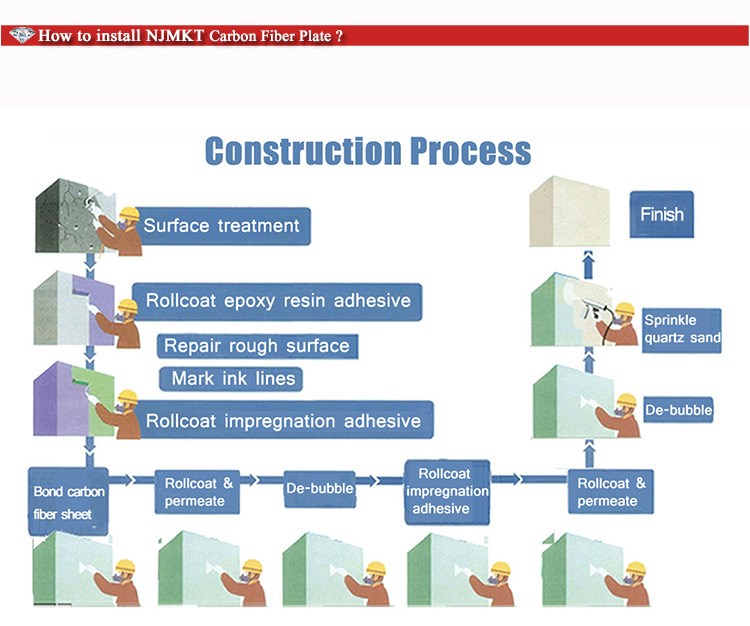

1. Surface treatment: Clean and abrade the surface of base material comprehensively to make sure there is not any attachment, if the paste parts have sharp edge, it should be abraded to soft round shape of a minimum radius of 20 mm. As the aim to use MKT-carbon fiber sheet is to improve the structural members, so the status of base surface should be paid attention to make sure that it could transfer load ability from the sheet to the structure surface.

2. Rollcoat epoxy resin adhesive and repair the rough surface (recommend to use surface leveling adhesive of our company), then mark the ink lines.

3. Rollcoat epoxy resin adhesive (recommend to use matching epoxy resin impregnation adhesive of our company) to the bonding surface, the adhesive must be used full enough.

4. Bond carbon fiber sheet which had been cut into suitable size to base material surface coating of adhesive, the sheet should be straight, extended. (If overlapping, the length of lap joints should be 20mm and the joints should not be in the middle but 1/3 of base material)

5. Re-rollcoat impregnation adhesive to the surface of carbon fiber sheet to ensure complete coverage of the surface of sheet and full impregnation of the fiber.

6. Use hard rubber stick or plastic scraper to roll and compact carbon fiber sheet repeatedly to keep it straight, extended, no bubbles, full penetration.

7. Rollcoat again the adhesive to soak and use scraper to scrape and de-bubble repeatedly.

8. Finally, sprinkle 3-6 mm sand (quartz sand) on adhesive-coated surface to make sure the adhesion of mortar cover.

Nanjing Mankate, founded in 2003, is a high-tech enterprise that specializes in researching, developing, manufacturing and selling a full range of anchoring and fixing systems, products and accessories for building reinforcement in construction industry.

Our company develops and manufactures more than 10 kinds of series products: undercut anchors, self-undercutting anchors, undercut panel anchors, adhesive anchors, carbon fiber sheet, carbon fiber plate, prestressed anchorage device, carbon fiber adhesive, crack sealing adhesive, steel bonding adhesive, anchorage adhesive, crack filling adhesive, and so on.

Our company strictly adheres to domestic and international standards to manufacture and manage, and we have received many honors. Our products was named as "Green Products of China Building Materials" in 2004, and awarded the honor of "Jiangsu AAA Quality and Integrity of Brand Enterprise" and "National Integrity of Corporate Membership" by CQSA in 2007. The trademark of Mankate has been recognized as "China Famous Trademark" in 2008. Nanjing Mankate passed ISO 9001:2008 quality system certification in 2011, and obtained honorary titles of "Jiangsu High Quality Products" and "China Famous Quality Products" in 2016, and so on.

NJMKT steadfastly holds on the belief of "product sale is just the first step", takes the benefit of clients as our starting point, appoints professional workers and technical engineers to inspect on construction site and communicate with construction party to help to detail the design plan, calculate overloading capacity of reinforcement materials, etc. NJMKT customizes various specifications of products according to every project requirements in the case of without affecting material performance.

FAQ

1. Where is your factory located? How can I visit there?

Factory Address: No.3 Jinhua Road, Guli Industrial Park, Jiangning, Nanjing City, Jiangsu Province, China

Office Address: Room306-307, West District of WandaJinjie, No. 291 Shuiximen Road, Nanjing City, Jiangsu Province, China

Tel: +86 (0)25-86651110 / 4008-945-118

Mobile: 13813833494/13813882444

Warmly welcome domestic and international customers to visit us!

2. Are you a manufacturer?

Yes, we are. We have our own factory to manufacture customized products according to customers' need. We are specialized in developing and manufacturing constructions reinforcement materials for more than ten years.

3. Is your sample free?

Yes, our sample is free but the shipping charge will be on your side.

4. How to get the quotation?

We have a full range of products with different sizes and specifications. Please offer us project information with details, material and size requirements of products or send us design drawing for our team to make complete solutions, then we could supply a most reasonable and favorable quotation for you.

5: What is your payment terms?

We prefer 100% T/T. For other payment terms we could discuss for every case.

6: How long is the lead time (producing time) ?

It depends on your order quantity and our factory production schedule. Usually we have a large stock of standard size products, and we can arrange and deliver the goods asap.

Every payment you make on Chovm.com is secured with strict SSL encryption and PCI DSS data protection protocols

Claim a refund if your order is missing or arrives with product issues, plus free local returns for defects on qualifying purchases